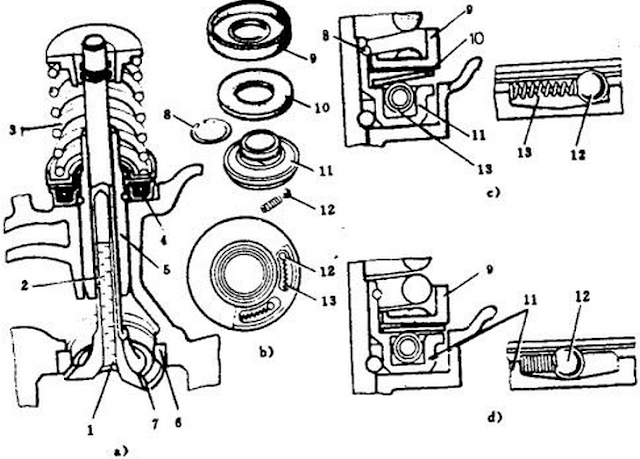

The exhaust valves of some auto mobile engines are made to rotate positively by a special mechanism during engine operation. This mechanism, known as the valve rotator, consists of a stationary housing with five ramplike grooves along its circumference that contain five steel balls loaded by return spring. Freely placed on top of the balls is a flexible washer (conespring) against which rests valve spring through the intermediary of a seating collar (Fig. 9).

As the valve is opened, spring is compressed and its increasing load causes the flexible washer to flatten out and force balls 12 down their ramps against the resistance offered by their return springs. As the balls roll down, they turn through some angle the flexible washer, seating collar 9, and valve spring together with the valve. When the valve is closed, the valve spring load decreases, the flexible washer deflects to acquire its initial conical shape and, abutting against a shoulder in housing, releases the balls which are then forced by their coil springs to return to their starting position.

In automobile engines, seating face of the exhaust valves is hard-faced with a heat-resistant alloy. Valve stem is made hollow and the cavity is filled 50 to 60% full with metallic sodium. The cavity is sealed off by stopper welded to the valve head. The metallic sodium liquefies, but does not vaporize at valve operating temperature and is capable of conducting heat much better than the valve material itself. Hence, the shaking of the liquid sodium due to the motion of the valve increases the heat transfer from the valve head to the stem and thence to the cooled region of valve guide, thus reducing the valve head temperature.

The intake valves heat less during engine operation, since they are cooled by the incoming air or fuel-air mixture on the intake stroke. To lessen the leakage (pulling) of oil into the cylinder through the clearance between the intake valve stem and its guide, some engines use an umbrella-type oil deflector cup of oil-resistant rubber placed on the valve stem. This extends over the valve guide and is held fast under the valve spring seating collar.

Valve guide supports the valve stem and guides its movement so that the valve face remains perfectly concentric with the valve seat and fits it without any skewing. Replaceable, or insert, valve guides are fabricated from cast iron or a cermet material and pressed in the cylinder head.

The intake and exhaust valve seats in many engines are formed by intake and exhaust valve seats in many engines are formed by insert rings of the heat-resistant cast iron that are pressed in the cylinder head. This facilitates their renewal during repair.

The valve spring provides the force necessary to close the valve and hold it tightly against its seat.

Valve springs may have their coils spaced either evenly or variably. Variably spaced valve springs, also known as the progressive rate springs, lessen the tendency toward surging as a result of resonance effects where such spring are used, the close-wound end (with less coil spacing) must be installed to-ward the valve had.

Some engines use two springs on each valve, which reduces the size of the springs, improves their reliability, and makes their operating conditions less arduous.

The motion-transmitting components of the valve mechanism serve to transmit motion from the camshaft to the valves. These include valve lifters, push rods, rocker arms with adjusting screws, and rocker-arm shaft with pedestals and locating springs.

Valve lifters, or tappets are made of steel. The tappets, also known as cam followers, may be either of sliding or of pivoting type. The sliding type may have a plain cylindrical or a mush-room-like form. Plain cylindrical tappets and mushroom-type tap-pets are provided with spherical seating to effect engagement with the pushrods. The bottom contact faces of these tappets may be either flat or slightly convex. To ensure a uniform distribution of wear over the face, the tappets are in duced to rotate as they reciprocate during engine operation. With flat-bottomed tappets, rotation is achieved by offsetting the tappet barrel axis relative to the cam axis, while in the case of spherical bottom tappets, this effected by making use of cams that are slightly tapered across their width, as a result of which the contact point between the tappet face and the cam is offset relative to the tappet axis.

Push rod serves to transmit force from the valve lifter to the rocker arm. Push rod may be fabricated from a solid or hollow steel bar. Push-rod ends are made in the form of either a ball or a socket and are thoroughly ground and heat treated. The lower end of the pushrod is ball-shaped. It engages the spherical socket in the valve lifter barrel. The upper end may-be either ball-or socket-shaped and it mates with the spherical socket or the convex ball on the end of the adjusting screw in the rocker arm.

The pivoting roller-type cam followers take the form of a hinged lever arm. On one end of the follower arm, there is a boss with a bore into which is pressed brone bushing to receive a hollow shaft supported in the cylinder –block-and-crankcase unit. The other end of the cam follower carries roller that rotates in a needle bearing and contacts the cam. Immediately above the roller, the follower is provided with an insert spherical seating that is press-fitted into a bore in the follower arm and engages the ball end of the push-rod.

thanks for sharing information

ReplyDeletehttps://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm