The engines can be classified in the following several ways: (1)perating cycle. (2)piston action, (3)piston con-nection, (4)cyflnder arrangement, (5)method of fuel inject-tion, and (6)speed.

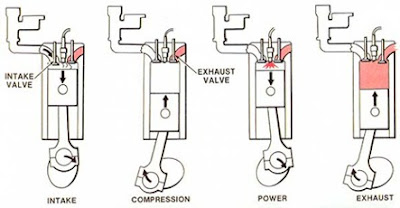

Operating cycle. Diesel and gas-burning engines can be di-vided into two groups based on the nymber of piston strokes per cycle, either four or two. An engine which neds four strokes to complete one cycle is a four-stroke cycle engine or, for short, a foru-cycle engine (Fig. 2). If it needs only two strokes to complete a cycle, it is called a two’stroke cycle engine or, for short, a two-cycle engine. Thus, a two-cycle engine fires twice as often as a four-cy-cle engine.

|

| Fig. 2 Operating cycle of four-stroke engine. |

Piston action. An engine’s piston action may be classified a (a) singleactmon (b) double-actmon, or (c) opposed-piston.

Single-acting engines use only one end of the cylinder and one face of the piston to develop power. This working space is at the end away from the crankshaft, that is, at the upper end of a vertical engine.

Double-acting engines use both ends of the cylinder and both faces of the piston to develop power on the up-stroke as well as on the downstroke. The construction is complicated; therefore, double-acting engines are built only in large and comparatively low-speed unis, generally to power motorships.

An opposed-piston engine has cylinders in each of which two pistons travel in opposite directions. The com-bustion space is in the middle of the cylinder between the pistons. There are two crankshafts; the upper pistons drive one the lower pistons the other. Note that each piston is single-acting; that is, it devel-ops power with only one face of the piston.

Piston connection. The piston may be connected to the up-per end of the connecting rod either directly (“trunk pis-ton”type), or indirectly (“crosshead” type).

In trunk-piston engines, a horizontal pin within the pis-ton is encircled by the upper end of the connecting rod. This by far the most common construction.

In crosshead-type engines, the piston fastens to a ver-tical piston rod whose lower end is attached to a sliding member called a “crosshead”, which slides up and down in guides. The cross-head carries a crosshead pin which in en-circled by the upper end of the connectin rod. This more complicated construction is required in double-acting en-gines. It is also used in some large, slow-speed, single-acting engines.

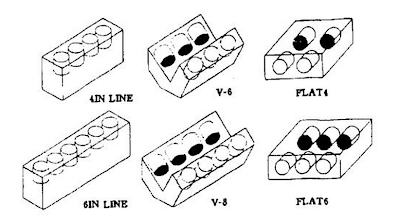

Cylinder arrangement (Fig. 3). The four basic cylinder arrange-ments of a diesel or gas-burning engine are: (a) cylinder-in-line, (b) v-arrangement, (c) flat, and (d) radial.

A cylinder-in-line arrangement. This is the simplest and most common arrangement, with all cylinders arranged vertically in line. This construction is used for engines hav-ing up to 12 cylin-ders. Engines are also built with horizontal cylinders, usually one or two, in a few cases with three cylinders.

|

| Fig. 3 Several cylinder arrangements. |

If an engine has more than eight cylinders, it becomes difficult to make a sufficiently rigid frame and crankshaft with an inline arrangement. Also, the engine becomes quite long and takes up considerable space. The v-arrangement, with two connectinng rods attached to each crankpin, pier-mits reducing the

engine length by almost one-half, thus making it much more rigid, with a stiff

crankshaft. It also costs less to manufacture and in.;tall. This is a common

ar-rangement for engines with eight, twelve, and sixteen cylinders. Cylinders

lying in one line are called a “bank”, and the angle between the banks may

vary, in manufacturing practice, from 300 to 1200, the

most common angles being between 400 and 72% (A complete circle is

360).

A flat engine is a v-engine with the angle between the banks

increased to 1800. This arrangement is used where there is little headroom,

as in trucks, buses and rail cars. Flat engines are also called “opposed-cylin-der”

engines.

In a radial engine all the cylinders are set in a circle and

all point toward the center of the circle. The connecting rods of all point

toward the center of the circle. The connecting rods of all the pistons work on

a single erankpin, which rotates around the center of the circle. Such a radial

engine occupies little floor space. by attaching the connecting rods to a

master disk surrounding the crankpin, as many as twelve cylinders have been

made to work on a single crankpin.

Method of fuel injection. Diesel engines are divided in-to

air-injection engines and solid or mechanical injection engines. Air-injection

engines use a blast of highly com-pressed air to blow the fuel into the

cylinder. Air injection was commonly used on early diesel engines but with the

development of solid-injection systems the air-injection en-gine is rapidly

disappearing.

Speed. All diesel and gas-burning engines may be di-vided

into three classes according to speed; low-speed, medium-speed, and high-speed

engines. Automotive diesel engines often run faster than 1, 200 rpm, but the great

ma-jority of other engines run between 350 and 1, 200rpm and are termed

medium-speed engines.

thanks for sharing information

ReplyDeletehttps://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm

https://www.glassdoor.com/Reviews/Employee-Review-Fluper-RVW15043091.htm